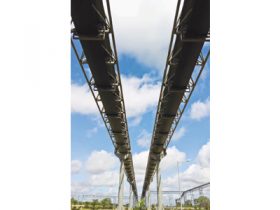

Belt conveyors have a vital application because of its capability of handling higher tonnage over long distance at lower cost than any other type of conveyor. They are used extensively for small and big capacity, as they are able to handle wide variety of materials economically.

ATS belt conveyors are performing numerous other functions in addition to transporting bulk materials, such as weighing, blending, sampling and stockpiling. Since the materials are carried on the belt, it is suitable for handling certain corrosive materials also.

The range of sizes of material handled onthe belt conveyors is limited only by the width of the belt. As belt conveyors get longer and conveyor systems get more complex, it is important to understand and utilize advanced design principals required to insure a robust, reliable and cost effective material handling Systems.

ATS offers segmental blades made out ofrubber / polymer /polyurethane depending upon the application with an option of having the lead edge cleaner tips made of Tungsten Carbide or Stainless Steel. Customers, rely upon ATS to provide application specific product, which are value priced, apart from meeting their ISO- 14000 requirements.