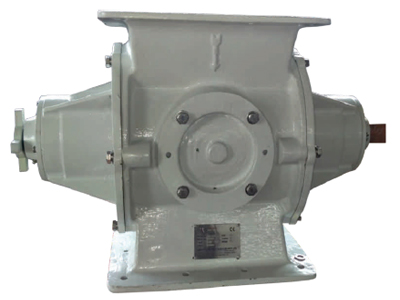

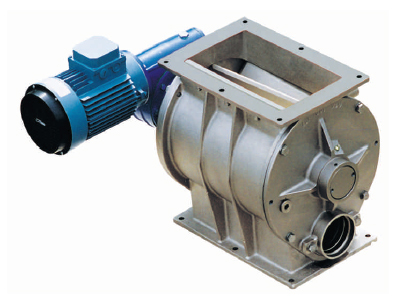

Rotary Airlock Valves, often referred as Rotary Airlock/ Rotary Valves, are a type of rotary feeders which are used in a wide range of applications in process industries where there is a need to minimize system air losses while transferring material between vessels with different pressures. These are employed to regulate the material flow from one chamber to another while maintaining a good airlock condition.

They are used to maintain pressure and provide an optimal airlock seal between different product conveying transitions, such as gravity to pneumatic conveying lines. An optimal airlock condition is essential to prevent air pressure loss in high pressure and high temperature conveying systems. Besides this, they are employed to regulate feeding and metering functionality of a standard feeder.

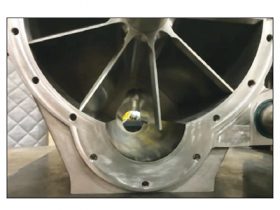

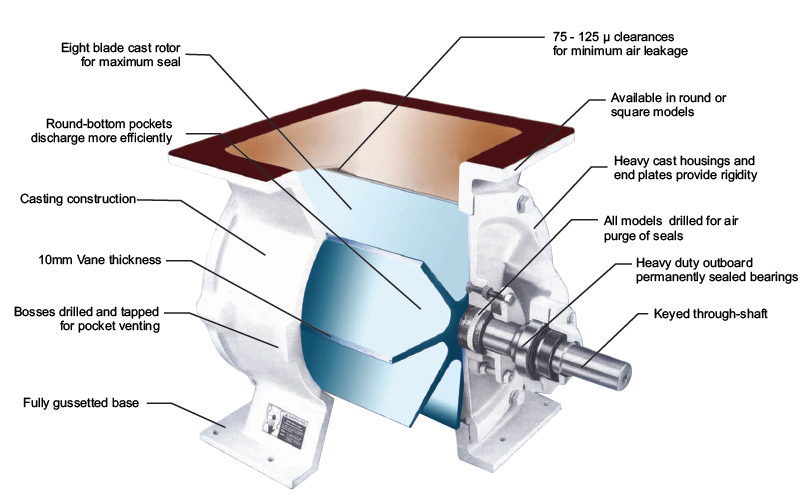

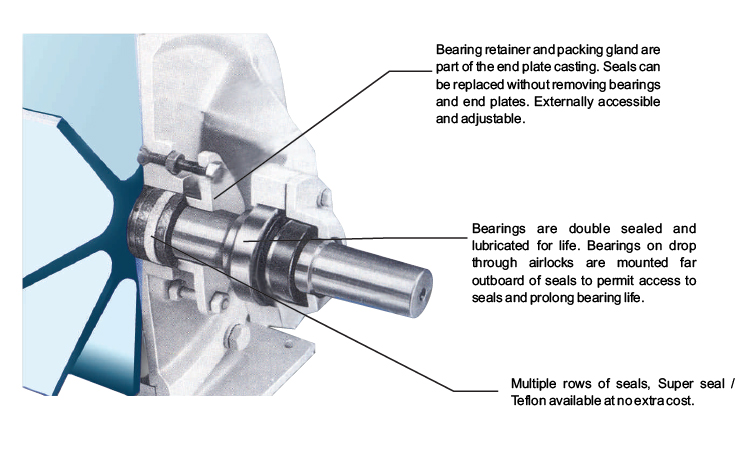

ATS builds a heavier airlock to closer tolerances, which means better sealing properties. Our airlocks are generally chosen for applications where air leakage and gas loss are of high important considerations, even though they are frequently specified for feeder applications because of their ability to withstand stress of heavy-duty feeder applications.

With ATS there are no double standards, all our standard valves are precision machined for close tolerances and minimal eccentricities.

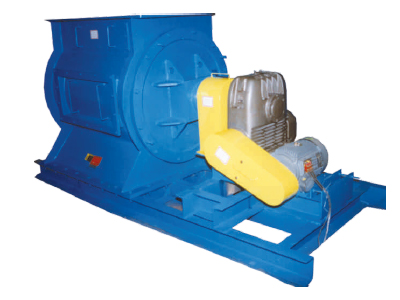

ATS also manufactures large fabricated drop through airlocks, which are built to last for large lumps and high capacities in sizes ranging from 800 dia to 2000 dia. These are fabricated from heavy gauge mild steel plates or any special materials as per client’s technical requirement.

ATS’ Drop through Airlocks are tailor made to user’s specific dimension, with supreme quality and strength, which can last long with low maintenance cost that too at thrifty prices in the market.