The Airslide conveyor was developed as a replacement for screw conveyors and belt conveyors where noise, maintenance, and dusting to the environment were issues.

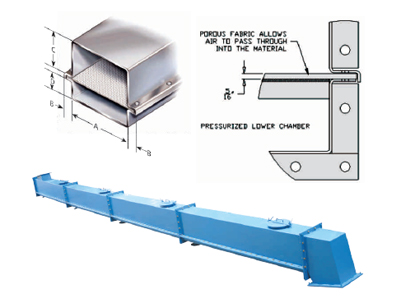

The most common application for the Airslide air activated gravity conveyor is to move from point to point any bulk dry free flowing powder that can fluidize. ATS air slide conveyors efficiently combine low air pressure and gravity to fluidize and convey most types of fine dry granular materials regardless of abrasive nature or bulk density. The only criterion is particle size and moisture.

The Airslide is best used to provide a means of conveying with little maintenance,no moving points, and dust tight making it extremely friendly to the environment. Since material moves on a cushion of air and the material particles tend to float, fabric wear is at a minimum.

Air slide conveyors can be used in a single straight run, but are equally as effective when used in large systems. Through the use of turn boxes, conveyors can easily change directions, merge, or split without the need for powered conveyors or diverters. Manual or powered shut off gates can be integrated into any point of the system to control flow.

The maximum range of the conveyors is limited only by the height of the source. Conveyors require a minimum of a 5- degree drop angle to function properly. A 10 degree angle is recommended for most applications.

Energy requirements are minimal because only a small volume of air at a low pressure is required to move material. Since the system is installed overhead, valuable floor space and added headroom are available for other purposes. By eliminating the need for massive support members, it permits a flexibility of plant design not available with straight-line conveyors.

Noise level is extremely low in the area surrounding the Airslide conveyor as the system’s air supply is the only moving part to generate noise, and it is enerally located in a remotely insulated area to further reduce noise.

Maintenance of the Airslide conveyor is very simple because there are no moving parts other than the air supply equipment, which also contributes to increased plant safety.

Airslide conveyors are used all over the globe in industries such as cement, food industries, power, petrochemicals, and the mining and minerals industries.

Salient Features:

- Uses low pressure air

- Conveys fine powders

- No moving parts

- Very low maintenance

- Simple installation

- Quiet operation

- Economical

- Energy-efficient

- High capacity

- High performance

- Versatile

- Reliable